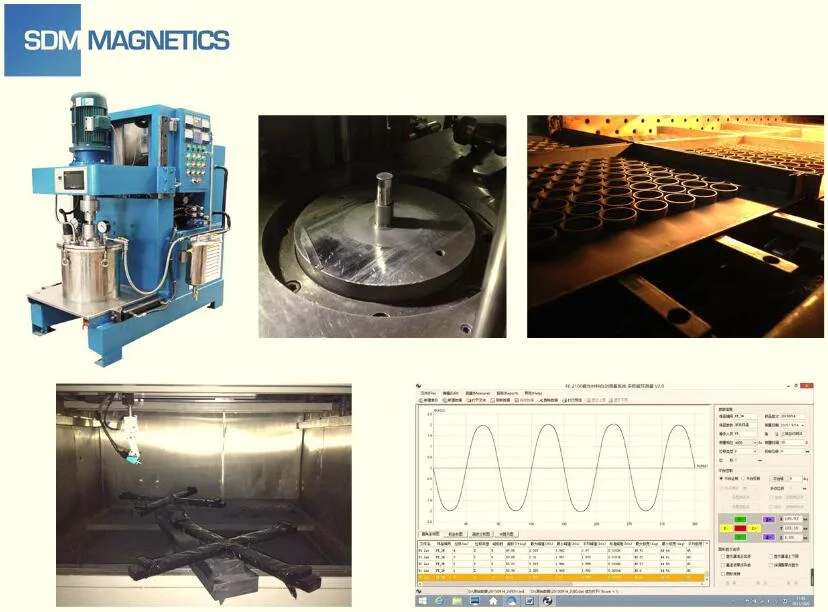

17 Years Experienced Free Sample High Solvent Resistance PPS/Plastic Bonded NdFeB/Neodymium Magnet

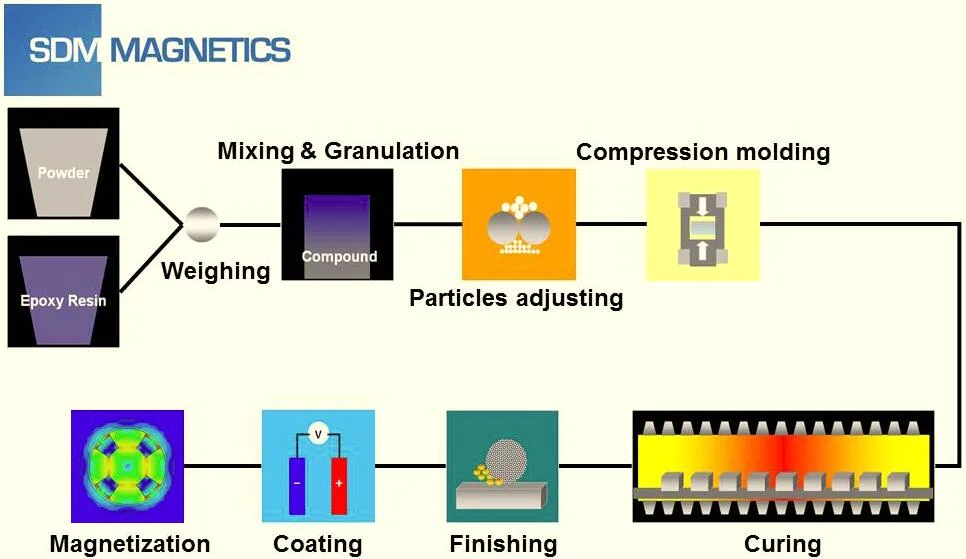

The process chart of NdFeB bonded magnet

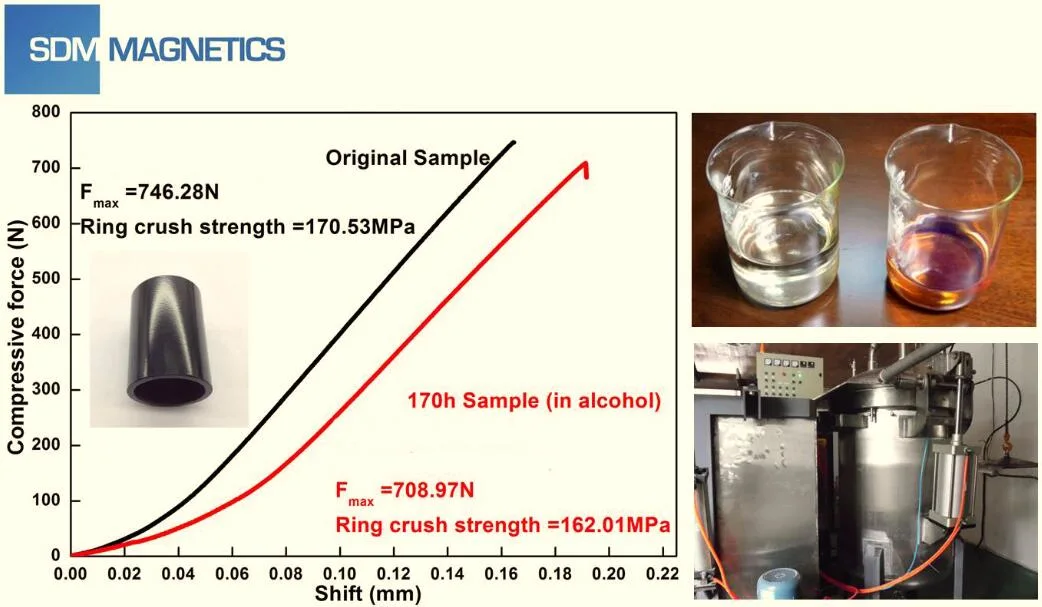

Infiltration technology of NdFeB bonded magnet

Magnetic properties of NdFeB bonded magnet

| BN-2 | BN-4 | BN-6 | BN-8 | BN-8A | BN-9 | BN-9H | BN-10 | BN-11 | BN-12D | BN-12L | |

Residual Induction Br | mT kGs | 300-400 3.0-4.0 | 460-520 4.6-5.2 | 550-650 5.5-6.5 | 620-670 6.2-6.7 | 620-680 6.2-6.8 | 650-700 6.5-7.0 | 650-700 6.5-7.0 | 670-720 6.7-7.2 | 680-740 6.8-7.4 | 720-770 7.2-7.7 | 730-770 7.3-7.7 |

Coercivity Hcb | kA/m kOe | 160-240 2.0-3.0 | 224-288 2.8-3.6 | 320-376 4.0-4.7 | 400-456 5.0-5.7 | 400-480 5.0-6.0 | 416-456 5.2-5.7 | 432-488 5.4-6.1 | 424-480 5.3-6.0 | 400-480 5.0-6.0 | 440-520 5.5-6.5 | 368-432 4.6-5.4 |

Intrinsic Coercivity Hcj | kA/m kOe | 440-600 5.5-7.5 | 504-680 6.3-8.5 | 600-720 7.5-9.0 | 640-800 8.0-10.0 | 1040-1280 13.0-16.0 | 680-800 8.5-10.0 | 920-1040 11.5-13.0 | 640-800 8.0-10.0 | 640-800 8.0-10.0 | 720-880 9.0-11.0 | 520-640 6.5-8.0 |

Max. Energy Product (BH)max | kJ/m3 MGOe | 19-26 2.4-3.3 | 30-35 3.8-4.4 | 44-52 5.5-6.5 | 64-76 8.0-9.5 | 65-73 8.2-9.2 | 68-76 8.5-9.5 | 71-80 8.9-10.0 | 76-84 9.5-10.5 | 80-88 10.0-11.0 | 88-96 11.0-12.0 | 80-88 10.0-11.0 |

Density ρ | g/cm3 | 5.6-6.0 | 5.6-6.0 | 5.6-6.0 | 5.8-6.2 | 5.8-6.1 | 5.8-6.2 | 5.8-6.1 | 5.8-6.2 | 6.0-6.2 | 6.1-6.3 | 6.0-6.3 |

Recoil Permeability μr | %/ºC | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

Tem. Coeff. of Br | ºC | -0.11 | -0.11 | -0.11 | -0.11 | -0.10 | -0.11 | -0.10 | -0.10 | -0.10 | -0.10 | -0.13 |

Curie Tem. Tc | ºC | 300 | 300 | 300 | 300 | 350 | 300 | 350 | 350 | 350 | 350 | 320 |

Max. Operating Tem. Tw | ºC | 160 | 160 | 160 | 160 | 180 | 160 | 180 | 160 | 160 | 160 | 120 |

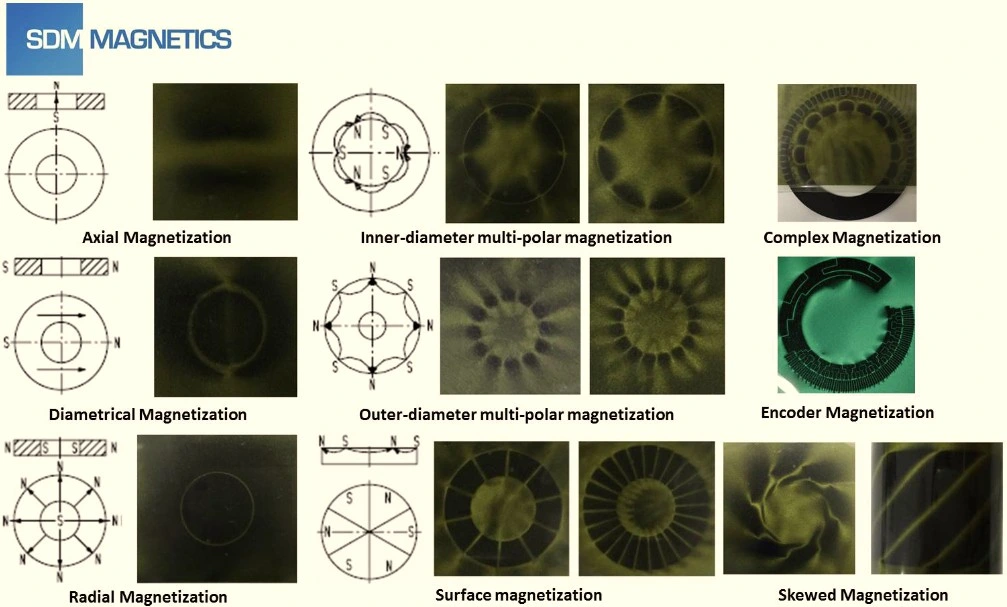

Magnetization of NdFeB bonded magnet

Surface treatment of NdFeB bonded magnet

Technology name | Introduction | Applicable scope | Feature |

Electrophoretic Coating | The most commonly used technique in industry. | Applicability to most compression magnets. |

|

Spray Coating | Spray the epoxy anti-corrosion paint to compression magnet's surface. | Apply to small sized work pieces, especially for arc-compression magnets. |

|

Anti-rust Oil Dipping | Anti-rust film can greatly improve compression magnet's anti-rust capability. | Especially suitable for small inner-diameter's compression magnet. |

|

Infiltration | Infiltrate anaerobic adhesive into compression magnet's voids by negative pressure. | Apply to extreme environment, such as oil or solvent. |

|

Exhibition

• We Will Join CWIEME Berlin every year;

• We Will Join HANNOVER MESSE every year;

• We Will Join CWIEME Chicago every year;

Shipping & Payment

• We have contract price with FedEx, DHL, UPS and TNT.

• We have our own Sea and Air forwarder Will Give you the best support about the freight fee.

• We accept T/T, Paypal, Western Union, ESCROW and L/C

SDM Reliability & Certificates

Standard Packaging & Factory

• Vacuum packaging for all Neodymium magnets and Neodymium magetic assemblies.

• Shielding box and wooden box to protect the Neodymium magnets during shipping.

Shipping Methods

• Contract price with FedEx, DHL, UPS and TNT to minimum your shipping cost.

• Experienced shipping forwarder for Ocean and Air shipments.

SDM Magnetics Co., Ltd. is a leading Chinese manufacturer of high performance permanent magnets and magnetic assemblies with ISO9001:2008, ISO/TS 16949 and ISO14001 certificates. SDM serves a variety of markets from consumer electronics, industrial automation, automotive, green energy, household appliances, medical, aerospace and telecommunications. SDM's magnets are used in motors, speakers, generators, sensors, compressors, MRI, magnetic chucks and separators etc.

To meet the more and more demanding markets, SDM has been concentrating on manufacturing technologies for quality stability and cost reduction. Since 2010 the company has been supplying magnets to General Motors' OEM with 0 PPM. With Dysprosium infiltration technology, we are able to offer competitive prices for high grade Neodymium magnets. The company has also built up a strategic cooperation with China's No.1 rare earth miner CHINALCO, which gives us strong and safe backup for rare earth raw materials.

SDM Magnetics now manufactures a comprehensive range of magnetic products including:

·Neodymium Magnet

·Injection Molding Magnets

·Samarium Cobalt

·AlNiCo (Aluminum Nickel Cobalt)

·Magnetic Assemblies

Over the last ten years SDM export 85% of its products to American, European, Asian and African countries.With such wide range of magnetic material options, our professional technicians are available to help solve your magnetic needs and choose the most cost effective material for you.

How to Find us ?

Our manufacturing plants are located in Tonglu, Hangzhou which are only one hour by car from Hangzhou airport or railway station.

We are also only one hour by train from Shanghai or Ningbo, pickup and drop off at Hangzhou Air/Train stations are available if you are traveling to Hangzhou from other cities in China.

FAQ

1: How fast can I get a reply?

You will receive our reply within 15 minutes during our work time 08:00 - 18:00(UTC-8).

2: Can I get free samples?

Free samples are available at SDM warehouse. However it may take minimum 7 days for production if your size is not on our stock list.

3: Are you able to offer best prices?

Magnets are functional products, the costs depend on how strong the materials you need. We believe the most suitable is the best, therefore SDM is keen to offer best prices to meet your target.

4: Are you able to provide best quality?

At SDM you receive products under guarantee of ISO9001, ISO/TS16949 systems.

5: What are your best lead-times?

Immediately shipments are available for stock magnets. For fresh materials, we need 7-15 days for production.

6: How can you make sure that my money is safe with you?

As an Alibaba Trade Assurance member, your funds are under protection of Alibaba group. Payment will not be released to vendor until buyer confirms receipt and good material of delivery.